Startseite » UD tapes

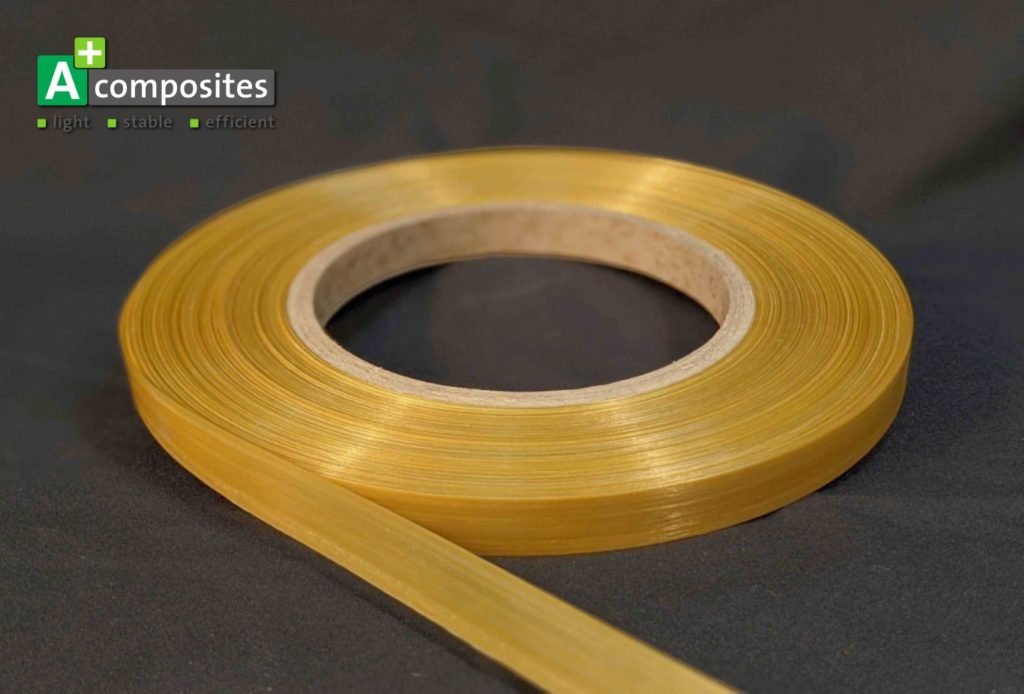

UD tapes: The material for plastic reinforcement

Optimum fiber reinforcement according to customer requirements

Material

- Fiber (i.a. CF, GF, UHMWPE)

- Polymer (i.a. PP, PE, PA6, PPS)

- Hybrid tape (Fiber- or platic blends)

Shape

- Width (0.25-4 in)

- Thickness (0.05-6 mm)

- Fiber volume (35 – 75 %)

- Fit width or slitting

Fabrication

- Biocompatibility

- Additivation

- Coloring

- Flame retardant

Material

- Fiber (i.a. CF, GF, UHMWPE)

- Polymer (i.a. PP, PE, PA6, PPS)

- Hybrid tape (Fiber- or platic blends)

Shape

- Width (0.25-4 in)

- Thickness (0.002-6 mm)

- Fiber volume (35 – 75 %)

- Fit width or slitting

Fabrication

- Biocompatibility

- Additivation

- Coloring

- Flame retardant

- Adhesive coating

The choice of material plays an important role in how efficient the UD tapes can be implemented. It greatly depends on the material of the component and the customer’s requirements. The choice of tape geometry depends on its application in the component, the performance required and whether the tapes go directly into the component or are processed first. Particularly in components in which many layers of UD tape are processed, the quality and dimensional accuracy of the tapes play a decisive role. As soon as the material and the geometry have been determined, further properties can be added: additived to achieve certain properties in the component, to protect the component from environmental influences, to color the tapes to match the component or to coat them so that the tapes can be easily bonded.

The way to the application of UD tapes

In order to determine the suitable UD-Tape for the corresponding application, samples are first produced according to customer requirements. This enables the customer to make an initial assessment of whether UD tapes are suitable for his application and what the next steps are for integrating them into the component. This is followed by successive adaptation and validation of the material and geometry as well as the manufacturing process. During these steps, A+ Composites GmbH supports its customers with its expertise.

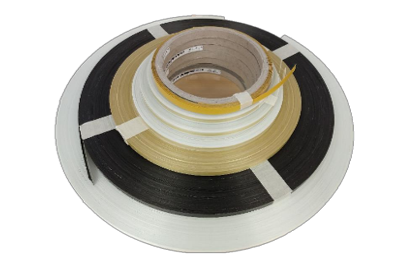

Which UD tapes does A+ Composites offer?

A+ Composites has already implemented over 30 combinations of fibers and matrices in customer projects. In addition, there are blends in which different types of fibers or plastic mixtures are used in one tape. Furthermore, A+ Composites offers tapes with special properties such as thermal protection and flame retardancy, as well as many different coatings. If you count variations in fiber volume content, the addition of additives and other adjuncts, and the coloring of tapes, A+ Composites has produced well over 250 different UD tapes since its founding in 2015.

Quality that makes the difference

By varying spool width and length, in-house slitting and tape production to custom widths, A+ Composites offers customers UD tapes in the exact dimensions that are optimal for their process. At the heart of the tape production is the in-line QA system for the thickness and width of the tapes. This allows customers to know the exact dimensions of each meter of the reel if needed. In its own laboratory, A+ Composites determines basic characteristic values and fiber distribution of of the different tapes. With its own developed process, A+ Composites achieves high dimensional accuracy and very good impregnation of the tapes.

This process is continually being improved and extended so that the tapes fit more and more applications.

Fiber reinforcement for many applications

UD tapes have a wide range of applications. In orthopedics the most commonly processed tapes are carbon polypropylene (CF-PP tape) and carbon polyethylene (CF-PE tape), but also carbon polycarbonate (CF-PC) due to its excellent bonding properties. Carbon polyamide (CF-PA) and carbon polycarbonate tapes are among the materials used in injection molding. For this technology, A+ Composites is developing new methods with a partner company to easily introduce the UD tapes into the process without having to change the mold. Carbon polyphenylene sulfide (CF-PPS) and carbon polyamide12 (CF-PA12) are most commonly used for pipes and containers. In the logistics industry, polyproyplene and polyethylene tapes are most popular in the glass or carbon variation (GF-PP/GF-PE). The choice of fibers depends on the required strength and the quality of the product.

Are you interested in our UD tapes or products made of tapes? Then contact us now: Contact