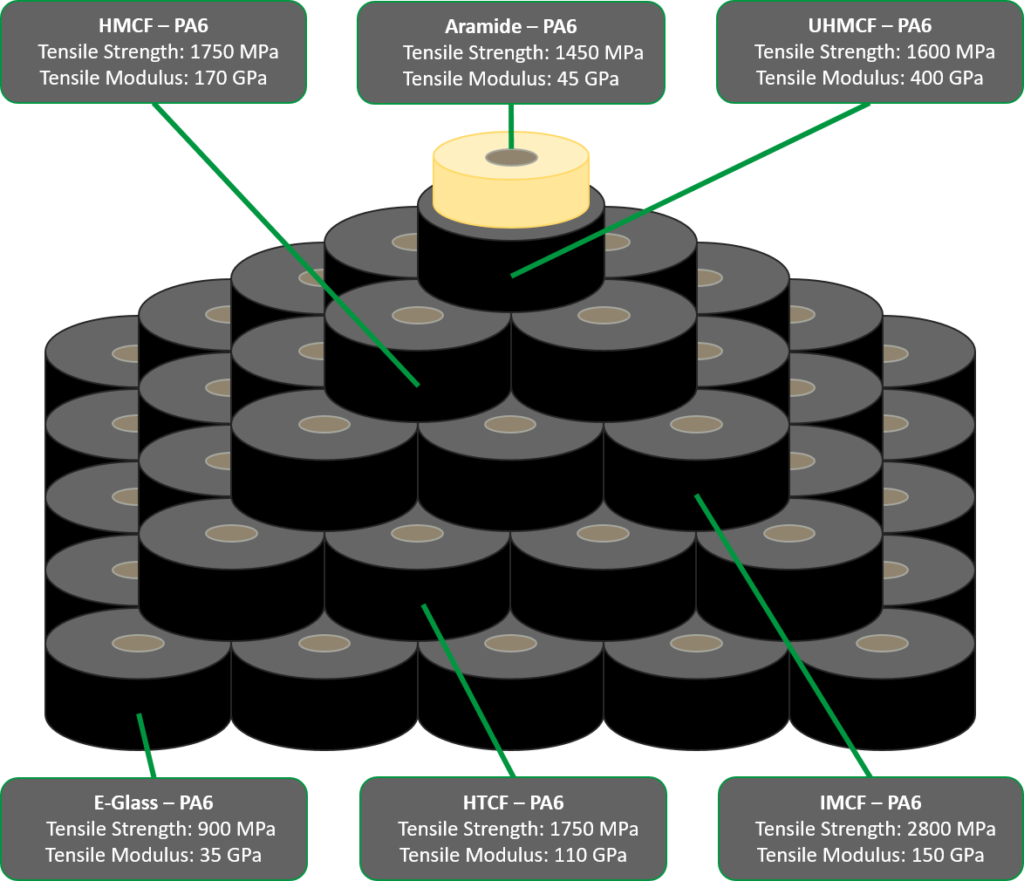

Pyramids have fascinated us since ancient times. The pyramid shape is one of the most popular forms to show distributions. And thus, the UD tape polyamide pyramid from A+ Composites shows the fascinating variety to combine polyamide6 (PA6) with different fibers. This results in composites that precisely meet the requirements of the specific application, while being easy to process and durable in use.

Polyamides – powerful polymers for technical applications

Many technical applications require polymers that have good mechanical properties, are economically viable and can withstand the environmental requirements of daily use.

Polyamides have all of these properties. They have better mechanical properties than standard polymers such as polyethylene or polypropylene and are less expensive than high-performance polymers. In addition, they have better fracture and abrasive resistance and are not affected by many chemicals. Additionally they are also resistant to lubricants and fuels at high temperatures.

Because of all these properties, polyamides have become the world’s third most widely used engineering polymers, replacing more and more metals, ceramics and other polymers since their discovery more than 80 years ago.

In engineering applications, PA6 is the most used type. PA6 is characterized by a good availability. Unlike many other polymers, it has a higher water absorption. As a result, components made of PA6 have better tenacity properties. However, the tensile strength and stiffness of the material are reduced by water absorption. This is of minor importance for fiber-reinforced PA6 components. The tensile strength and stiffness properties of PA6 are negligible compared to those of the fibers.

PA6-UD tapes – versatility with a multiplied performance

The versatility of PA6 gains another dimension through the variety of fibers that can be combined with this all-rounder material. The composites are ideally suited for lightweight constructions since they have multiplied mechanical values.

How great the gain in performance is depends largely on the fibers used and how they are distributed in the polymer. The best results can be achieved if the fibers are oriented along the load paths. Unidirectional tapes (UD tapes) come closest to this ideal.

Depending on the mechanical and economic requirements of the application, different fibers are necessary. The lowest-cost variants are UD tapes with E-glass fibers. The fiber reinforcement increases the Young’s modulus and tensile strength tenfold in fiber direction.

Carbon fibers are usually classified according to their strength and Young’s modulus. Standard carbon fibers are high-strength fibers (HT fibers), which are characterized by good tensile properties and a solid Young’s modulus. If fibers have an average Young’s modulus between 280 – 350 GPa and a tensile strength of 3500 – 7000 MPa they are called IM fibers. In some classifications, carbon fibers from the IM class with very high tensile strengths are also listed as UHT fibers. Carbon fibers with a Young’s modulus between 350 – 600 GPa and tensile strength between 2500 – 5000 MPa are called HM fibers. A few fibers reach tensile strengths between 2500 – 4000 MPa and Young’s moduli of 600 to 900 GPa. These are called UHM fibers.

Aramid fibers impregnated with PA6 are suitable for special applications. This combination is particularly interesting where very high damping properties, good fatigue strength and high impact strength are required.

PA6-UD tapes from A+ Composites for a wide range of applications

A+ Composites has been manufacturing UD tapes with PA6 matrices, among many other fiber-matrix combinations, for over three years. By varying the fibers, the fiber volume content and the dimensions, A+ Composites has already produced over 50 different variants with this polymer. Therefore, the special feature of these tapes is that they are adapted to customer requirements in terms of both mechanical requirements and processing parameters.

This makes them suitable for many different processing methods, from tape winding, tape laying and injection molding to hot pressing. In addition, the tapes can be produced as non-slit tapes or slit tapes. The advantage of non-slit tapes is that the fibers are not damaged at the edge, which means that the material has better mechanical characteristics than a tape that has been cut to width.

Fun fact: Among other materials, basalt was used in the Pyramids of Giza. Soon a basalt fiber UD tape will also be part of A+ Composites UD tape pyramid.